Fine Beautiful Info About How To Build A Chassis Table

This free farmhouse table plan features x braces on either side and a small industrial touch with a metal pipe reaching across the bottom of the table.

How to build a chassis table. I started with four cement blocks. Drill pilot holes, then screw the leg braces to the seat supports and center top board. That will create a beveled edge to help shed water.

I started by ordering up some 3″ x 2″ x ¼” box tubing for the frame rails. Selecting the chassis frame tubing. Two in the front and two in the back.

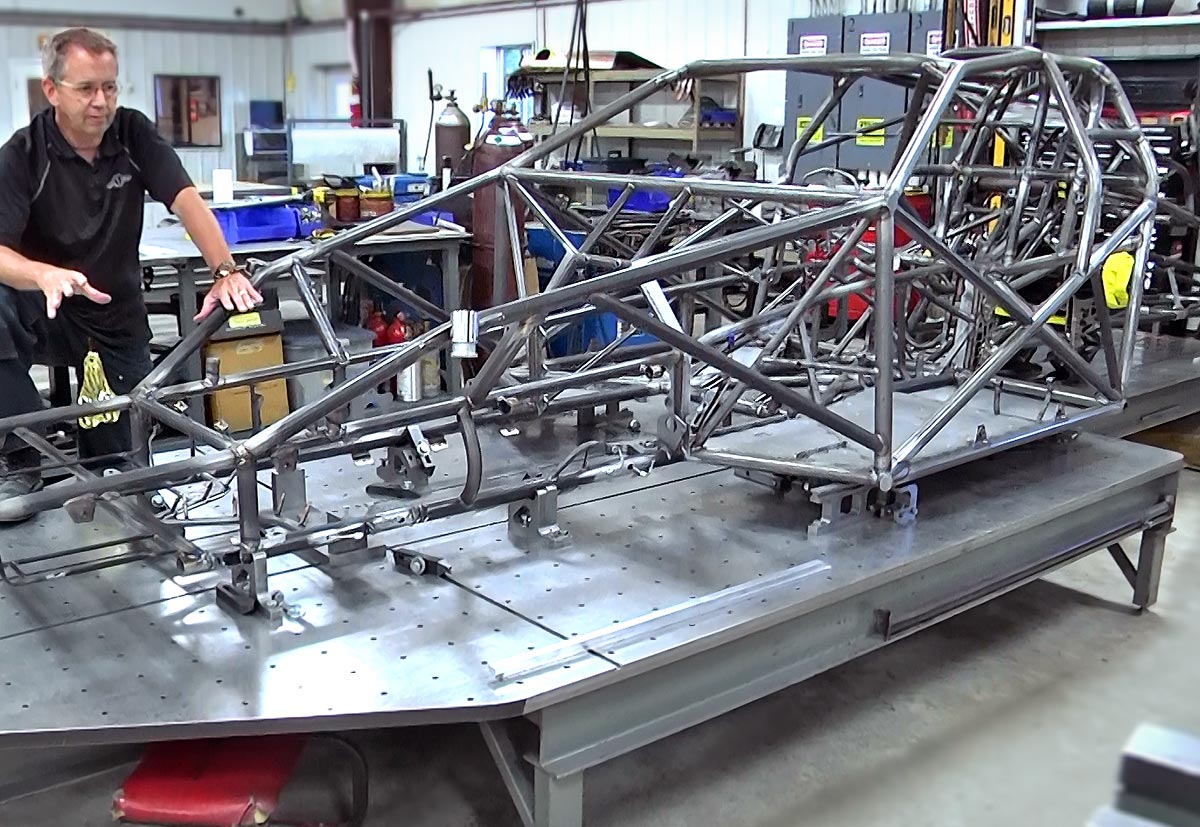

Cut the side trim boards (j) and the back trim board. Before we can start on the build of our tube chassis buick regal, we need a level place to work, so today i'm going to show you how to make your own chassis. A chassis table is essential for any fabricator tackling larger fabrication projects.

Drill pilot holes, then screw the leg braces to the seat supports and center top board. Then i ran a peice of two by four tubung across both pairs of blocks. Matt uses salvaged materials to make his version of a diy chassis table.

Any discussion of how to fabricate something (anything) starts with the assumption that accurate measurement in three dimensions is a given. Building a simple hot rod chassis from scratch step 1: Tim explains how to make a basic chassis jig that can be used when building your own race car.like and subscribe if you find these golden nuggets of informat.

Flip the table over and align the leg braces (e) with the top as shown in figure a. Starting with the front bar i leveled it. Tim mcamis explains how to make a basic chassis jig that can be used when building your.